Concrete 3D printing is set to reshape the construction scene

Written by: Anais Masetti

Publish Date: August 18, 2020

All can agree that construction is not the fastest moving industry in terms of technological progress and overall innovation. So why the sudden enthusiasm for 3D printed buildings? Well, the application of this technology in construction could bring significant economic, social and environmental benefits.

Therefore, additive building processes like the ones used in the cases above are set to be greatly influential in the future of construction. Below we give an overview of the key drivers behind this trend and of the innovative businesses at the wheel.

Why is 3D printing relevant for construction?

According to Markets and Markets, the 3D printing construction market is projected to grow from USD 3 million in 2019 to USD 1,575 million by 2024, at a CAGR of 245.9 % between 2019 and 2024.

One of the main drivers of this growth lies in its economic advantages. Using printers to automate some of the building processes can mean less labour is needed which could also allow for cost-cutting. While the technology still has some way to go to make do without any human intervention, the premise is that in the near future 3D printers will be able to raise buildings from the ground on their own in a matter of days rather than months (as they could theoretically work day and night uninterruptedly).

This might represent a threat to construction workers, but it could make for safer work settings too. This is especially true of building sites that are located in hostile environments with extreme weather. In fact, the world’s largest 3D printed edifice is built in a desertic area. On the other hand, countries with ageing populations (like Italy, Japan and many more) are facing an impending shortage of young professionals. 3D printing could prevent construction players from resorting to hiring undocumented migrants and as a result reduce the chances of modern slavery.

The economic advantages presented by this technology has other positive implications for social welfare too. For instance, more affordable housing could be built thanks to 3D printing. While this is not a widespread practice yet, low-cost homes and social housing could be created in a shorter time and probably at a better quality than is possible through traditional means, considering the limited budgets provided for such projects.

Moreover, additive building is an environmentally sound practice as it produces less waste than traditional construction and fabrication methods. Only the amount of material needed for a part is utilised in 3D printing, hence the quantities of wasted material through this process are usually minimal. Material waste can often be reused to 3D print other structures. On top of this, on-site 3D printing means fewer machines, parts and other components (like prefabricated walls) have to be transported to the construction site. This represents an opportunity to cut carbon-emissions related to trucks bringing equipment to building sites.

Tech startups furthering this trend

Several small businesses have taken on the opportunities created by the construction industry’s growing appetite for 3D printing. Some honourable mentions include Apis-Cor (maker of the world’s biggest building) and WinSun (maker of the tallest building) as well as Cobod and Voxeljet. These companies all offer innovative printing hardware and materials suited for architectural prototyping and building.

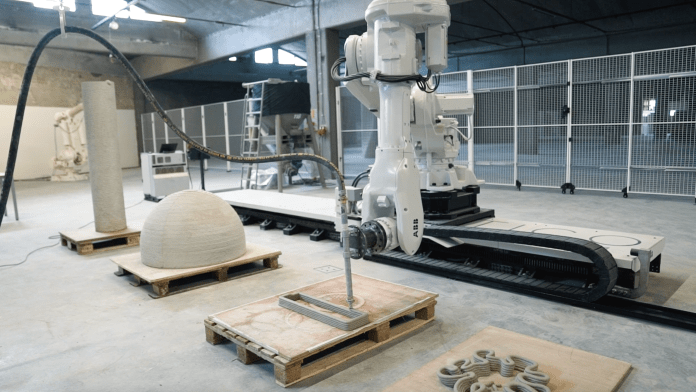

Early Metrics has also rated an emerging player that has shown good promise in this field: Concr3de is a Dutch startup creating machines and materials for (you guessed it) concrete and stone 3D printing. Its printing materials can be used to prototype the interior and exterior of buildings, for restorations and as refractory materials for castings. The startup is not only selling its printing machines and consumables to its customers but also offering R&D services.

Concr3de’s stone printing solution represents an interesting enabler for architectural creativity as it allows for greater flexibility and aesthetic freedom in the production of strong structures. As part of its R&D offering, the startup also allows customers to go further in the customisation of their end-product by helping them develop their own materials.

A startup with concrete results

In 2019, Concr3de caught the attention of the media and by proxy of the public when it proposed to apply its technology to the reconstruction of the damaged Notre Dame cathedral. Recreating a small section of it as a proof of concept, the startup showed that the rubble and burnt parts of the monument could be reused to 3D print its gargoyles and other architectural features with high accuracy.

Aside from this ingenious POC and PR success, the startup is showing signs of significant growth potential. Founded in 2016, Concr3de has already been involved in multiple collaborations with household names and institutions such as Zara Hadid Architects and the Faculty of architecture of Innsbruck (UIBK). The rating conducted in December 2019 by Early Metrics also highlighted good levels of commercial traction considering the startup’s young age.

As often with young businesses, the founding team is the main source of strength for this startup. It’s a duo in this case, Matteo Baldassari and Eric Geboers. Both founders are experienced architects and therefore have an in-depth understanding of both the technical and commercial specificities of their products and markets. Concr3de’s 3D printing materials also set the startup apart as they allow for the production of highly durable and stable structures as well as high-accuracy casts.

While they will undoubtedly face growing competition, Concr3de is operating in a market that is likely to take off soon. Governments and construction companies are bound to continue seeking new technologies to make building processes safer, more cost-efficient and sustainable. Hence, stone 3D printing and other additive building technologies will hopefully enable a better and greener future for the construction sector.

About the Author

This article is written by Anais Masetti

Read the original post here.